|

|

|

|

| ModuLab |

UniLab |

Environmental Room |

| Modular workspaces constructed to meet specific laboratory needs. pre-engineered modular construction for fast delivery. |

Dedicated work environment features

an all-glass modular construction, distinctive high tech

angled upper panel. |

Temperature controlled room enclosures are

engineered to maintain precise

environmental conditions. |

|

|

| HEMCO modular rooms are engineered and built to meet

your exact size and design specification. Wall

panel options are available to meet thermal, chemical resistance,

sound, and fire rated

requirements.

Roof / ceiling systems can provide load-bearing

capacity or be suspended for overhead supply

plenum. Modular room systems are a cost and time effective answer

to your enclosure needs.

The per-engineered design

allows you to immediately put a facility into

use and quickly adapt with minimal installation

and costly down time. |

|

| ModuLab Designated Lab Work Area |

|

|

|

Modular workspaces are constructed to meet your specific laboratory

specifications.

- Pre-engineered modular construction for fast delivery. On

time, On budget

- Adaptable to existing lab

space or expansion into warehouse

space

- Can be easily assembled, moved, modified and re-erected as

needs change

- Insulated wall system features chemical resistant and easily

cleanable surface skin panels

- Optional furniture layouts, fume hoods, controlled supply and

exhaust air systems

|

|

|

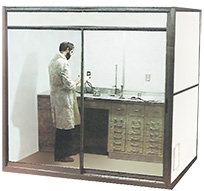

| UniLab Regulated Lab Work Area |

|

|

Dedicated work environment featuring

an all-glass modular construction

with a distinctive high tech

angled upper panel.

- Allows for visual observation of personnel or process in the

enclosure

- Serves as secondary containment

between the fume hood and

the lab

- Transparent walls provide an open unconfining full vision work

space

- Capable of incorporating existing walls as part of the enclosed

area

- Utilizes a greater amount of surrounding light

- Isolates and contains hazardous operations

|

|

|

| Environmental Room |

|

|

Controlled room enclosures are

engineered to maintain precise

environmental conditions.

- Temperature and humidity control with defined plus / minus tolerances

- Optional modular cam-lock

wall, ceiling, and floor

panel systems

- Air handling units can be floor or roof mounted

- Airlocks, interlocks and insulated window options are available

- Room monitoring and control systems

- Applications include CMM, Tappi, PM 2.5 weigh rooms

|

|

|

| Modular Lab Gallery |

|

|

|

| Quick Ship Modular Clean Labs |

|

| HEMCO ModuLab room structures are innovative, pre-engineered modular laboratory workspaces that are built to your exact process, size and design requirements, for ventilation and safety. |

|

|

4’ X 8’ QC Lab w/base floor |

|

8’ X 12’ Calibration Lab |

|

10’ X 16’ Clean Lab |

|

|

Modular Labs and Applications • Industrial Quality Control Laboratory

Hazardous Materials Testing

CMM/Calibration Lab

Controlled Environment Rooms

Designated Control Rooms

Additional Lab Space |

| |

As technologies change, companies need facilities that can immediately be put into use or quickly adapt with a minimum amount of installation, time, and cost.

The Modular Clean Lab features a pre-engineered modular wall panel system that is a cost effective and time efficient alternative to traditional construction. It gives you a fully equipped, high quality enclosure that is easily expanded or relocated as needs change. Determine where the room should be located, assemble the Modular Clean Lab, connect services and start your process.

The Modular Clean Lab can fit a wide range of applications. Wall panel options are available to meet thermal, chemical resistance, sound, and fire control requirements. Room roof panels can offer load bearing capacity and suspended ceiling systems are available for pressurized overhead supply plenums.

Complete environmental control systems can be supplied to meet your precise specifications. Temperature, humidity, room pressure, and variable exhaust control packages are engineered into a convenient and versatile control panel.

Modular Clean Labs can be shipped knocked-down to fit through a standard doorway for easy on-site erection. If desired, it can be shipped pre-assembled for turnkey operation complete with laboratory fume hoods, furniture, and all component equipment to meet your laboratory requirements.

You can detail your specific requirement on our convenient specification planner. |

| |

|

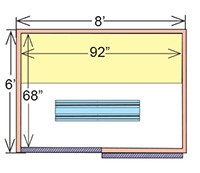

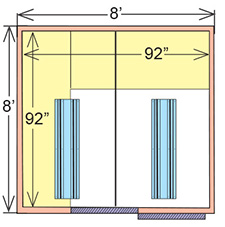

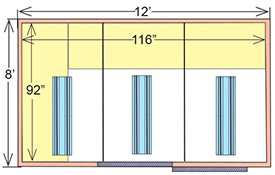

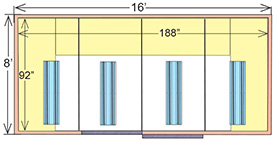

| Standard Sizes of UniLab Modular Labs (custom sizes available to your specs) |

|

| Rooms include: laboratory base cabinets, countertops (yellow), fluorescent lighting (blue), and slide entry door (purple). Request a tech data sheet for room specifications. |

|

|

|

|

Plan View Room # 1

Cat. No. 80068 (8’ x 6’ X 8’) |

Plan View Room # 2

Cat. No. 80088 (8’ x 8’ X 8’) |

Plan View Room #3

Cat. No. 80812 (12’ x 8’ X 8’) |

Plan View Room #4

Cat. No. 80816 (16’ x 8’ X 8’) |

| Cat. No. |

Room #1

Description |

Qty |

| 80068 |

8’w X 6’d x 8’ h Modular Lab (3) Solid Walls |

1 |

| |

8’ wide Sliding Door |

1 |

| |

Air Grill |

1 |

| |

Vapor Proof light fixture with switch |

1 |

| |

Lab furniture and

worksurface,

on (1) wall |

1 |

|

| Cat. No. |

Room #2

Description |

Qty |

| 80088 |

8’w X 8’d x 8’ h Modular Lab (3) Solid Walls |

1 |

| |

6’ wide Sliding Door |

1 |

| |

Air Grill |

1 |

| |

Vapor Proof light fixture with switch |

2 |

| |

Lab furniture and

worksurface,

on (2) walls |

1 |

|

| Cat. No. |

Room #3

Description |

Qty |

| 80812 |

12’w X 8’d x 8’ h Modular Lab (3.5) Solid Walls |

1 |

| |

6’ wide Sliding Door |

1 |

| |

Air Grill |

1 |

| |

Vapor Proof light fixture with switch |

3 |

| |

Lab furniture and

worksurface,

on (2) walls |

1 |

|

| Cat. No. |

Room #4

Description |

Qty |

| 80816 |

16’w X 8’d x 8’h Modular Lab (3.5) Solid Walls |

1 |

| |

8’ wide Sliding Door |

1 |

| |

Air Grill |

1 |

| |

Vapor Proof light fixture with switch |

4 |

| |

Lab furniture and

worksurface,

on (3) walls |

1 |

|

| *If a Fume hood, sink or HEPA filtered supply is required, consult Factory for details. |

|

|

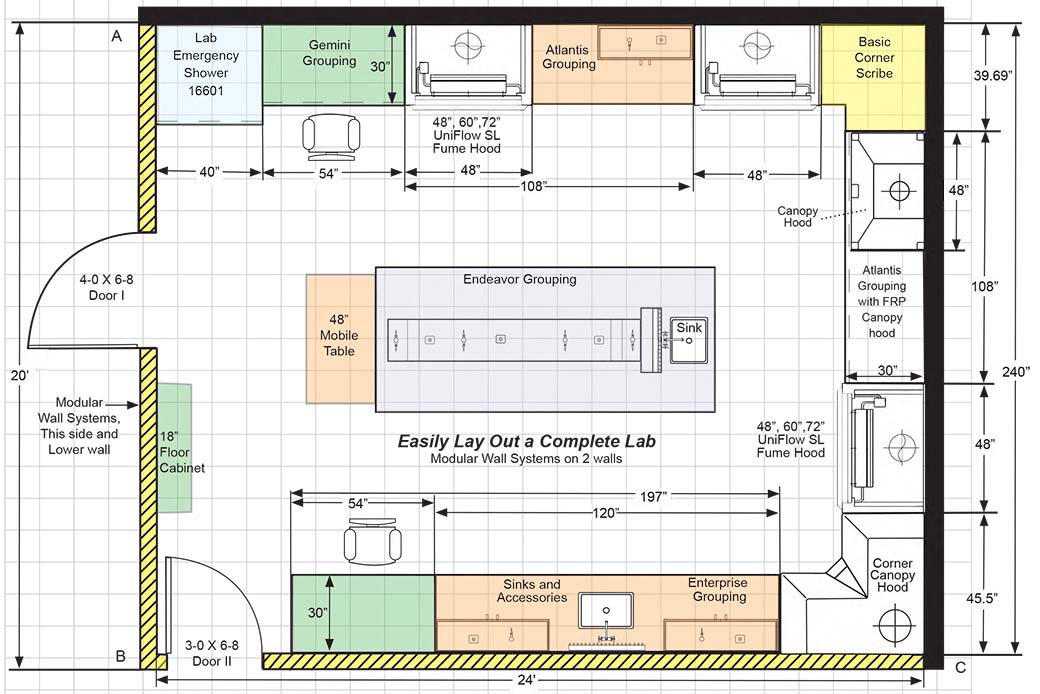

| The HEMCO Plan-A-Lab enables you to conveniently lay out your lab furniture and your pre-engineered modular clean lab. For more information request the Modular Clean Room Brochure. Shown below is a 20’ X 24’ (2) wall system. Existing walls in black, new walls in yellow slash mark. |

|

|

|

| Furniture Layout Instructions |

|

1. Determine the dimensions of the area (wall to wall) where the proposed lab furniture will be located.

2. Position the countertops in desired location for optimal work flow efficiency and ergonomics.

3. Remember to allow a wider dimension of 42” for aisle width. Higher traffic aisles require a wider dimension.

4. Locate water drain and supply locations for required sink placement.

5. Decide if backsplashes, rear curbs, or island reagent shelves are required.

6. Specify the style of grouping or individual cabinet selection.

7. If utility services are required, such as electrical services, service fixture keycocks, DI or cold water faucets, and safety services, please locate their placement on the benchtops.

8. Specify fume hood model or size if required . |

|

Should a modular room structure be required to isolate the lab work area from a surrounding warehouse or production area, follow these steps.

1. Specify inside dimension requirements, verify available height clearance above the room, and verify the distance to the roof above. see above diagram.

2. Determine the number, type, and size of doors required and whether windows are needed.

3. If air conditioning is required, please detail the number of people, heat load of proposed lab instruments, ambient surrounding temperature, and the desired location for HVAC (e.g. floor, wall, roof, etc.).

4. Advise the class of clean room and if an airlock will be necessary.

5. Consider if the proposed lab can be accessed from a dock area. |

|

|