| Clean Rooms Modular HEPA Filtered |

|

|

|

| Modular HEPA Filtered Cleanroom |

Laboratory Suites |

Modular Clean Room |

| Clean Rooms, Class 1,000, Class 10,000, Class 100,000, modular, cost effective, relocatable, HEPA Filtered |

Constructed using modular wall panel design system, sealed clean room suspended ceiling, HEPA filtration |

Containment Control Systems, engineered to safety control the sampling and weighing of powders |

|

|

|

|

| Softwall Clean Rooms |

CCS Containment Control Systems |

Quick Ship Modular Clean Rooms |

| HEPA filtered Class 100 environment. Workstation has clear acrylic side walls, hinge-up front viewing window. |

Clean Labs,Modular work areas, provide exhaust systems to vent laboratory fume

hoods, pre-engineered, HEPA filtered |

Clean rooms, Modular work areas, provide exhaust systems to vent laboratory fume

hoods, pre-engineered, HEPA filtered |

|

|

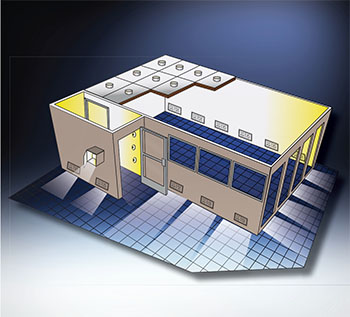

Modular HEPA Filtered Clean Rooms

• Where critical levels of cleanliness must be maintained,

HEMCO Modular UniLab pre-engineered modular

system offers a cost-effective alternative to conventional

construction while providing quality, durability and

modular clean room performance.

• HEMCO Modular UniLab modulars are movable and

expandable and to provide years of usability and

versatility.

• HEMCO Modular clean room wall systems can interface

with the modular clean room floor, ceiling and mechanical

components to provide a clean workspace that

maintains optimum airflow, pressure, temperature,

humidity and cleanliness.

• HEMCO Modular clean rooms can also be free standing structures, independent of the surrounding area. Rooms can be engineered to meet special size requirements.

• At HEMCO, we understand your needs. Modular construction allows fast, easy installation as well as

design flexibility to meet your changing needs without

sacrificing quality. |

|

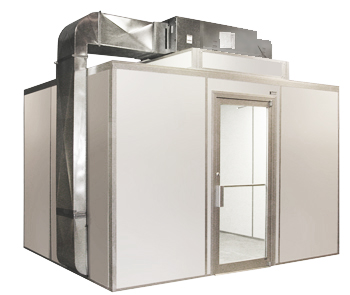

| Modular Clean Room, Class 100,000 |

| Experience you can depend on

• Since 1958, HEMCO has been manufacturing quality

laboratory equipment. We can provide the modular clean

room furnishings, and certification to meet your specifications.

• HEMCO Modular clean room systems are built to your exact

specifications to ensure optimal performance.

Pre-engineered

modular design minimizes construction costs

and delays. |

|

|

|

|

Modular clean room, Class 100, with

airlock HEPA Filtered |

Compounding Modular clean room, Class 1000, with filtered airlock, HEPA Filtered |

Calibration Clean room, Class 10,000

HEPA Filtered |

|

Construction Features

• Wall and ceiling panels are chemical resistant,smooth and

non-porous for easy cleaning and decontamination. Panel

surfaces can be constructed of fiberglass, stainless steel,

coated steel or aluminum.

• Convenient access to HEPA filters and lighting allows

them to be serviced from inside the room.

• Special airlocks, gowning areas and pass-through can

be designed into the modular clean lab. |

|

Concept to Completion

• HEMCO’s experienced technical staff will gladly assist

in the design and engineering of your clean room from

concept to

completion.

• Technical staff will work closely with you to answer

questions or

suggest solutions, helping to develop a

modular clean room to

your exact specifications.

Download a HEMCO Modular clean lab / Clean room

specification planner (bottom of this page). |

|

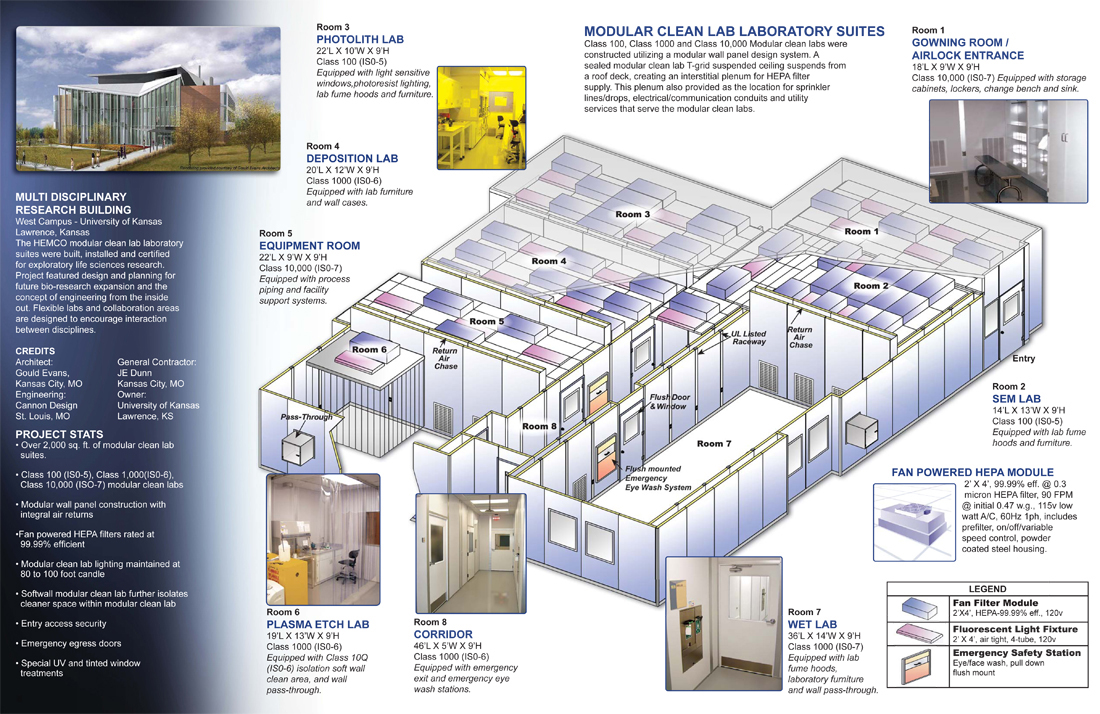

| Laboratory Suites |

|

|

|

| Innovative Modular Clean Rooms and Labs |

|

|

|

|

Modular HEPA Filtered Clean Room

HEMCO modular work areas are designed to maintain Class 1000 to Class 100,000 environments and also provide exhaust systems to vent laboratory fume hoods and equipment. The pre-engineered modular room system is cost effective, time efficient and a clean alternative to standard construction. |

|

Features:

Complete filtration systems that recirculate or are single-pass can be supplied. Lab furniture layouts, including cabinets, countertops, sinks, fume hoods and utility services, can be designed to meet your specifications. The modular wall panels feature a composite resin surface that is modular clean lab compatible and chemical resistant. |

|

|

|

| Softwall HEPA Filtered Clean Rooms |

|

|

|

|

Softwall HEPA Filtered Modular Clean Rooms

HEMCO Softwall Modular clean rooms provide a versatile, reliable and flexible solution for budget-sensitive and specific need requirements. The clear vinyl curtains can be strip or solid, allowing access where desired. HEPA filtration can be engineered to meet Class 100 to Class 100,000. The airflow is single-pass. |

|

Features:

Optional static dissipative curtains are available and casters can be supplied allowing the softwall modular clean lab to be moved. Softwall modular clean rooms are offered in standard sizes of 6’x 4’, 8’x 4’, 8’x 8’, 8’x 12’, 8’x 16’, 12’x 12’ and 12’x 16’. HEMCO also builds to meet your size and design needs. |

|

|

| CCS Containment Control Systems |

|

|

|

|

CCS Containment Control Systems

Engineered to safely control the sampling and weighing of powders to meet FDA, COSSH and GPM requirements. Available in class 100 to class 100,000 environments that are negative to the surrounding area to ensure containment. |

|

|

Features:

Containment booth is available either unitized (shipped assembled) or modular (assembled in the field) construction. Clear vinyl strips allow for easy pallet/drum access. Lighting, fans and controls are included.

Optional casters are available for mobile applications.

Standard sizes are 6’ x 4’, 6’ x 6’, 8’ x 4’ and 8’ x 6’.

Other sizes can be built to exact needs. |

|

|

| Quick Ship Modular Clean Rooms |

|

| HEMCO Modular Clean Room Structures are innovative, pre-engineered modular laboratory workspaces with HEPA filtered supply air, built to your exact process, size and design requirements, for ventilation and safety. |

|

|

Modular Labs and Applications • Industrial Quality Control Laboratory

Hazardous Materials Testing

CMM/Calibration Lab

Designated Control Rooms

Additional Lab Space |

| 4’ X 8’ QC Lab w/base floor |

As technologies change, companies need facilities that can immediately be put into use or quickly adapt with a minimum amount of installation, time, and cost.

The Modular Clean Room features a pre-engineered modular wall panel system that is a cost effective and time efficient alternative to traditional construction. It gives you a fully equipped, high quality enclosure that is easily expanded or relocated as needs change. Determine where the room should be located, assemble the Modular Clean Room, connect services and start your process.

The Modular Clean Room can fit a wide range of applications. Wall panel options are available to meet thermal, chemical resistance, sound, and fire control requirements. Room roof panels can offer load bearing capacity and suspended ceiling systems are available for pressurized overhead supply plenum.

Modular Clean Rooms can be shipped knocked-down to fit through a standard doorway for easy on-site erection. If desired, it can be shipped pre-assembled for turnkey operation complete with laboratory fume hoods, furniture, and all component equipment to meet your laboratory requirements.

You can detail your specific requirement on our convenient specification planner. |

|

| 8’ X 12’ Calibration Lab |

|

| 10’ X 16’ Clean Room |

|

|

|

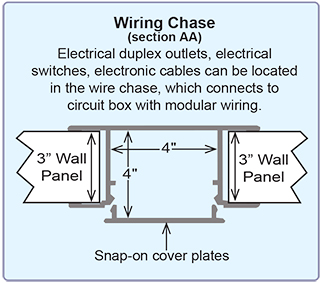

Room Construction Features: wall panels are Class A and are mounted into a 3” clear anodized aluminum framing. Standard wall panels are 48”w x 120”h x 3” thick and are constructed with a foam core sealed between 1/2” gypsum and surfaced with chemical resistant composite resin panels with smooth white finish.

T-Grid Ceiling System:1-1/2” Aluminum ceiling grid with white painted finish positioned 8’ above floor. Includes all connectors, suspension hardware to hang from corrugated steel roof deck.

Mylar Ceiling Panels: have sealed edges for spaces not occupied by fan filter units or light fixtures.

Entry Door: (1) 36” W X 80” H Door with viewing window, passage lever and hinges & lock.

Windows:Nominal 46” W X 39” H tempered glass, double glazed, flush mounted in an anodized aluminum frame.(optional windows can be added to meet your specs)

Lighting: LED light fixtures, Class I Div I & Class II Div II to suit specifications.

Single-Pass Design: Ambient surrounding air is drawn into the Clean Room Fan Filter Units at the ceiling level. The filtered air passes into the clean lab and is transferred out of the room through either the fume hood or general exhaust grills. Room is clean but under slight negative pressure.

HEPA Filters: 2’ X 4’ Fan Filter units, 115V with 99.99% HEPA Filter, variable speed control and all other standard specifications. |

|

HEPA Filtered Supply Air: 2’ X 4’ Fan Filter units, Module features a 99.99% efficient.@ 0.3 micron HEPA filter with, 90 FPM @ initial 0.47 w.g., 115v low watt A/C, 60Hz 1ph, includes prefilter, on/off/variable speed control, powder coated steel housing.

Clean Aire In-Line Carbon Filtration Exhaust Air: Filters are loaded with virgin coconut activated carbon to efficiently absorb organic solvents and acid fumes. The filter pack housing features a hinged access door with gaskets and spring latches for convenient filter changes.

Exhaust Blowers: Standard (STD) belt drive steel blower and impeller wheel are epoxy coated for superior chemical resistance. Explosion-proof blowers (EXP) have epoxy coated, non-sparking aluminum impeller wheel. V-belt drive and adjustable pulleys permit field balancing. |

|

|

|

|

|

|

|

|

|